Call Us On

9821588203 / 0 8108828586

Welcome to Harison Microsystems

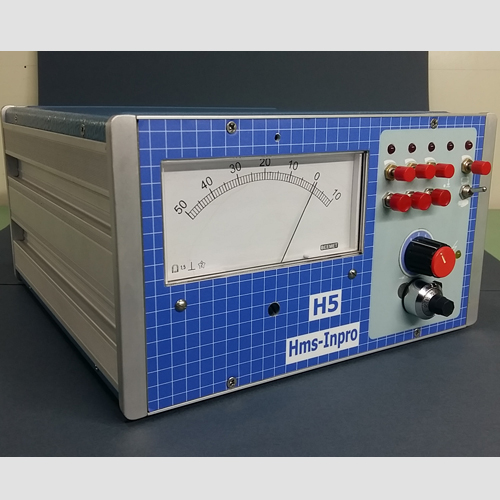

In Process Amplifier (HMS-H5) dual has application in measuring diameter of interrupted gear part during grinding operation. Measuring head continuously monitor diameter of interrupted surface and display measurement on the Analog dial . Amplifier has settable damping memory to smooth out interrupted signal.

Amplifier has been provided with Analog Dual sensitive meter, three set points, Adjustable Auto retraction time setting, Offset adjusts Potentiometer.

Selection rotary switch has been given for setting measurement independently and Sigma position to add both reading ( A,B,Sigma )

Measuring head connected to In Process Amplifier continuously measures work piece diameter during grinding operation and compares with set-points presets in amplifier. In-feed controls of machine are control and Grinding wheel retract signal is applied once diameter of the component reaches set final zero value.